Are EVs Environment Friendly?

Dr Arunaditya Sahay

Introduction

As per NITI Aayog 80% of 2 wheelers and 3 wheelers, 40% buses, and 30% to 70% of cars in

India will be EVs by 2030. Against this, “between 2019-20 and 2020-21, 2 wheeler EV rose

by 422%, 3 wheelers by 75%, 4 wheelers by 230% and Electric Buses by1200%,” said Nitin

Gadkari, Minister of Road Transport and Highways. We need to stop and think whether this

break neck speed of introduction of EVs will lead to net zero – our ultimate target towards

sustainable development.

Road transport is one of the high GHG emitting sector and is therefore needs a deep look.

Countries, world over have planned to transit their road transport to EVs. The heaviest and

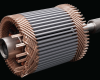

costliest component of an EV is its battery. An electric vehicle battery (EVB) or traction battery

powers the electric motors in battery electric vehicles (BEVs) or hybrid electric vehicles.

Unlike starting, lighting, and ignition (SLI) batteries, electric vehicle batteries are lithium-ion

and built for high power-to-weight ratio and energy density. Because they reduce vehicle

weight and improve performance, smaller and lighter batteries are preferred. Many existing

battery technologies have lesser specific energy than liquid fuels, limiting all-electric vehicle

range. Lead–acid, nickel–cadmium, nickel–metal hydride and lithium-ion batteries have been

used in electric vehicles; these are rechargeable batteries. Unlike nickel-cadmium batteries,

presently used lithium-ion batteries can be depleted and recharged every day at any charge

level.

The battery, which constitutes a substantial portion of an electric vehicle’s cost as well as

weight, has an adverse environmental impact across the supply chain. The industry’s growth

has prompted a focus on establishing ethical battery supply chains, especially the supply of

lithium poses numerous challenges besides being a crucial geopolitical issue.

Recycling of Batteries

Battery recycling involves the reuse and reprocessing of batteries, with the goal of diminishing

the disposal of batteries as material waste. Since batteries contain harmful chemicals and heavy

metals, their improper disposal poses environmental risks, leading to concerns about water and

soil contamination. Therefore, proper recycling of batteries is essential to align its use in line

with environmental and health requirements.

As global electric mobility continues to rise, there is a growing demand for electric vehicle

(EV) batteries. This surge in demand has spurred significant expansion in battery production,

with the capacity expectation of over five terawatt hours (TWh) per year. This calls for giga

factories worldwide by 2030. Additionally, there is a notable increase in the volume of EV

batteries reaching the end of their lifespan, with projections indicating that over 100 million

vehicle batteries will be retired in the next decade. If they are not fully recycled, they become

environment damager.

Shifting from fossil-fuel-based to electric mobility brings environmental benefits and cost

savings for consumers but transitioning our transportation system necessitates the design and

scaling of new supply chains. This dilemma presents a chance to create a more stable, robust,

efficient, and sustainable green supply chain than the fossil-fuel and ICE vehicle sector but the

disposal of batteries at the end of life will still remain a problem.

Despite a large EV transition in China, Europe, and the US, most battery material suitable for

recycling still comes from consumer electronics cells like those in laptops and other household

items and cell manufacturing scrap from faulty batteries that don’t pass quality control. A new

battery facility can generate up to 30% scrap during cell manufacturing, causing a significant

recycling and disposal problem. Presently, end-of-life EV batteries are more prevalent in

China, where EV adoption has been widespread. The production scrap of cells across the world

will remain the dominant source of battery recycling materials until 2030. Beyond this, the

end-of-life EV battery volumes will surpass cell scrap generation.

Mining of Lithium and Nickel

The composition of electric vehicle (EV) battery chemistry differs across models and suppliers.

However, a fundamental lithium-ion pack generally requires crucial heavy metals. Primarily,

lithium is a key component; many packs, however, also incorporate varying amounts of cobalt

and nickel. It is important to note that these metals are not readily available in their pure forms.

Cobalt and lithium don’t naturally occur in a pure state, and nickel is found only in trace

amounts outside of ore. This is where the process of mining and refining becomes essential,

which comes with associated economic and environmental costs.

Companies acquire cobalt as a byproduct of nickel mining, and the extraction of metals from

the ore typically involves one of two methods: hydrometallurgy or pyrometallurgy. The

selection of the extraction process depends on the specific compound and the concentration of

the metal and so is the level of environmental damage. Hydrometallurgical extraction utilizes

an aqueous solution to extract the desired materials, while pyrometallurgical methods rely on

heat to separate the desired components from the undesired ones.

Prior to the 1990s, lithium extraction, primarily involved mining it in solid form from a few

minerals. In contemporary times, the majority of lithium is sourced from brine located beneath

salt beds. The extraction process entails drilling for the brine, pumping it to the surface, and

allowing it to sit in evaporation ponds for several months to years until it achieves the desired

lithium concentration. Subsequently, the liquid is transferred to a processing facility, where it

undergoes filtration and chemical treatment to produce the final product, typically lithium

carbonate in the context of an electric vehicle (EV) battery.

From an environmental perspective, mining necessitates extensive land, water, and energy

resources. The chemicals utilized in mineral processing must be sourced, and the proper

disposal of unwanted materials can create hazardous waste. Further, mining activities can lead

to adverse environmental impacts such as contaminated soil and water, air pollution, soil

erosion, and landslides.

Taking all these into consideration, should we not have a relook on the transition policy for

road vehicles even though India has discovered lithium deposits?

Related Posts

[wpforms id="5714"]

Categories

Latest Posts

Rare Earth Magnets May Demolish EV Dreams

May 26, 2025Are EVs Environment Friendly?

May 22, 2025B